Ebbsfleet Primary School

Challenge

To provide a full detailed design tender package for in compliance with ESFA requirements, the School Specific Brief, Planning Conditions and a BREEAM Very Good target.

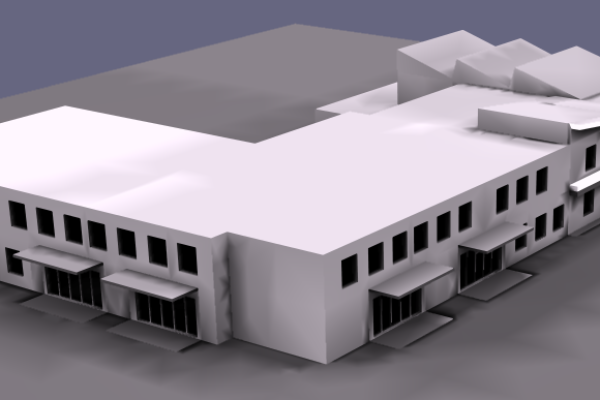

Modular buildings are lightweight constructions that offer little thermal mass. This can cause overheating where significant internal heat gains may arise. This is a challenge in schools that are assessed against the rigorous standards of ‘BB101 - Ventilation, thermal comfort and indoor air quality 2018’.

A value engineering exercise indicated that natural ventilation terminals could be used to ventilate the space and reduce cost pressure on the budget. However, the Local Authority expressed concerns about the visibility of plant to the saw tooth roof of the assembly hall.

Opportunity

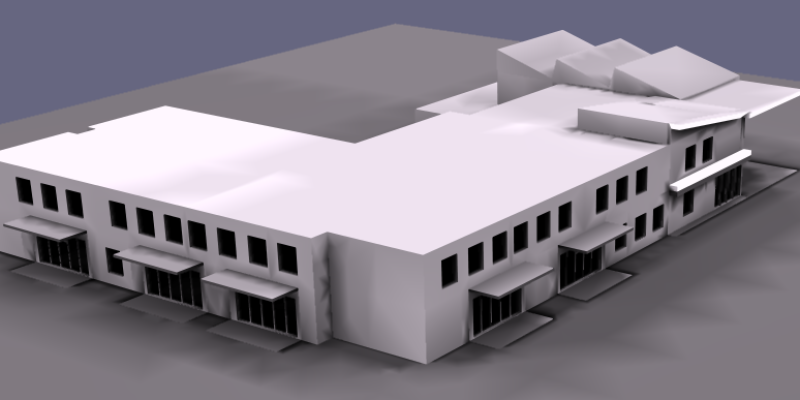

To use modular construction to deliver a cost effective project within a reduced programme span.

To demonstrate that with some derogations to the ESFA specification the school could be built using modular construction in compliance to the School Specific Brief, the requirements of BB101 and achieve the BREEAM Very Good target.

To integrate hybrid and natural ventilation into a new modular project to create a comfortable sustainable school building.

Engineering and Design

Thermal mass can be a useful tool in handling overheating. In warm environments energy associated with the internal heat gains is taken up by the dense constructions and is not easily given up. When the space becomes unoccupied and cools down the massy elements give up the heat energy ready for the another cycle the next day. In the lightweight highly insulated constructions of modular builds there is nowhere for the heat to go raising internal temperatures. Cooling technologies such VRF systems and air conditioning or means to extract warm air need to be introduced.

Our Approach

We worked closely with the design team to produce a particular specification and coordinated detailed design for the mechanical and electrical building services for tender.

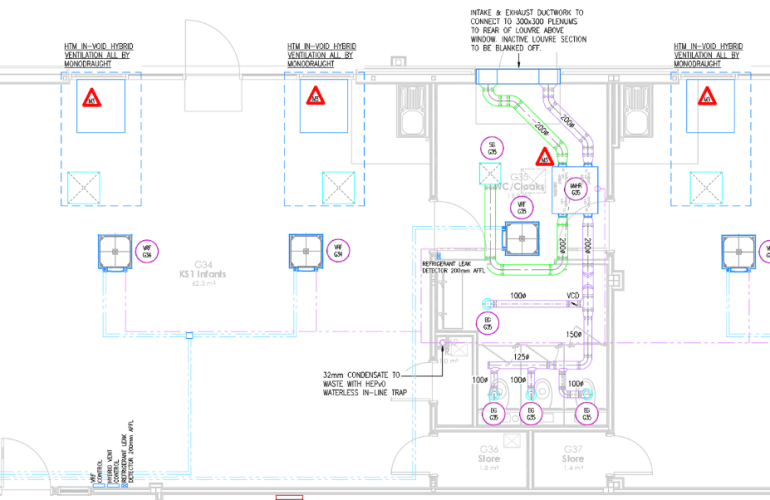

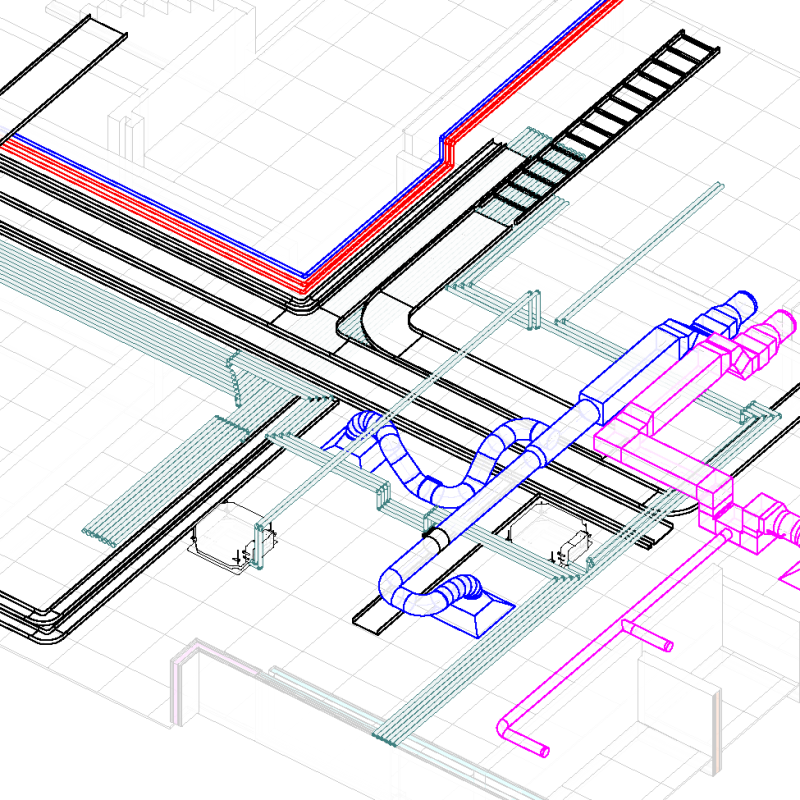

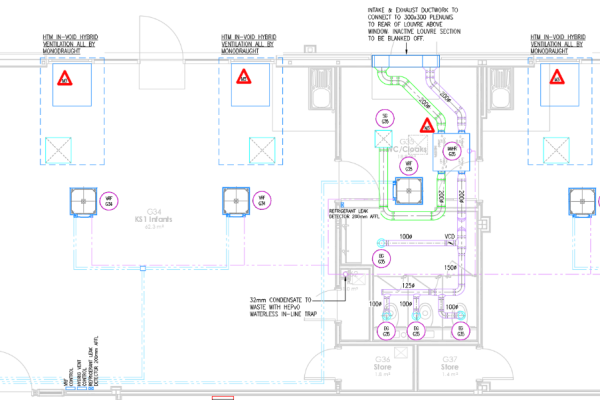

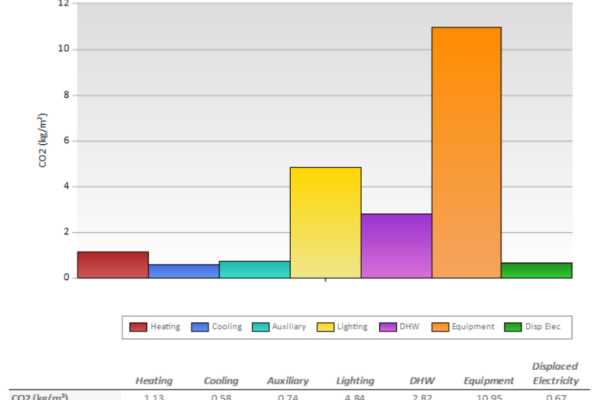

We developed an HVAC strategy including hybrid ventilation units, VRF systems and natural ventilation to avoid overheating. The ventilation provided the basis for management of elevated temperatures and CO2 level. The cooling function of the VRF systems is used to trim peak temperatures.

We worked with the manufacturer of the natural ventilation terminals to generate options on their appearance that would satisfy the Planning Officers’ requirements.

Dynamic thermal analysis using EDSL TAS software was used to develop the energy model for the building so that the BB101 report, Part L calculations and building heating and cooling loads could be produced.

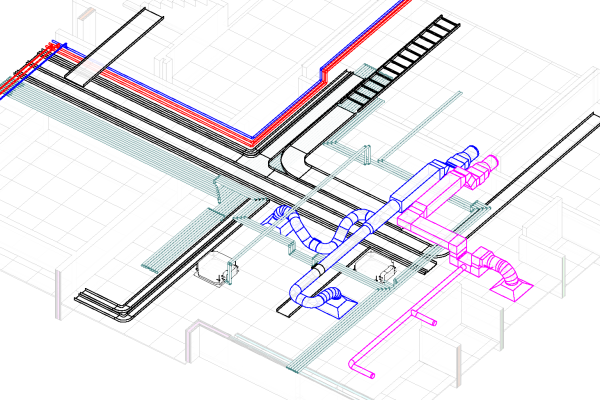

MEPworx buildings services design package was used to calculate ventilation duties, duct sizes and piped services sizes.

Trimble Prodesign was used for electrical cable calculations. Lighting design was carried out using ReluxPro.

Detailed design tender drawings were produced in Autocad, with a coordination model in Revit MEP

Outcomes

Planning Consent Granted

Very Good BREEAM Rating

Coordinated Building Services Design

Project delivery within budget, to programme

A great contemporary primary school project