University Sports Science Block

Challenge

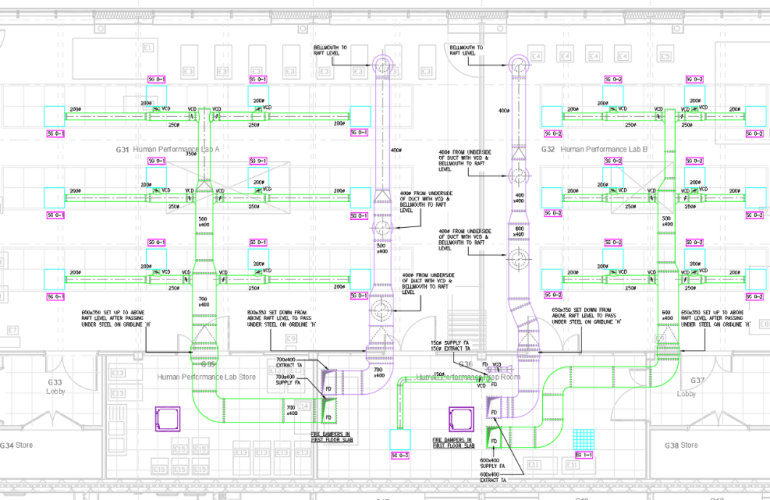

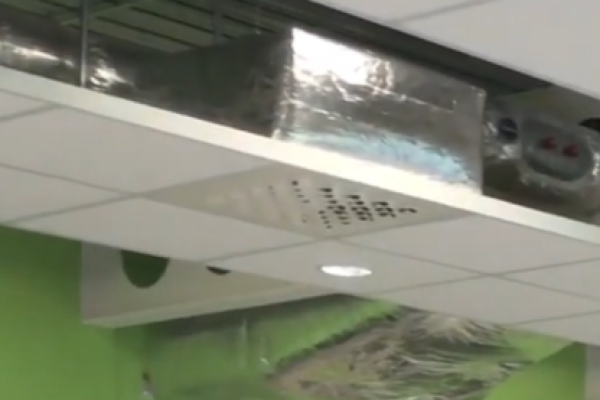

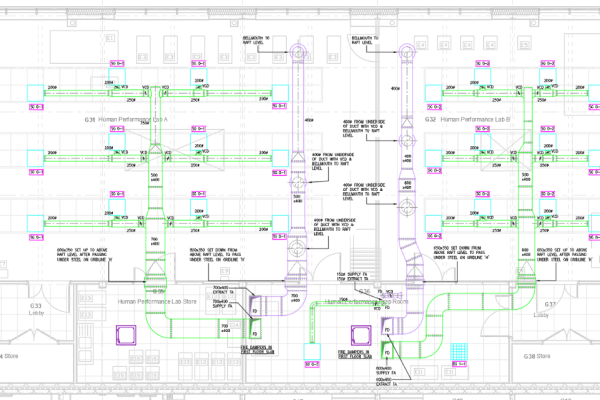

The new build extension had to sit within the horseshoe shape of the existing building with the building services extending off the current utility supplies. The project could not exceed the installed utility supply capacities. The Human Performance Laboratories need to operate to exacting environmental conditions for experimental integrity. Both laboratories need to operate independently during experiments and as a single space when the folding partition wall is pulled aside. The operation of communicating rooms could not be allowed to disturb the laboratory conditions.

Opportunity

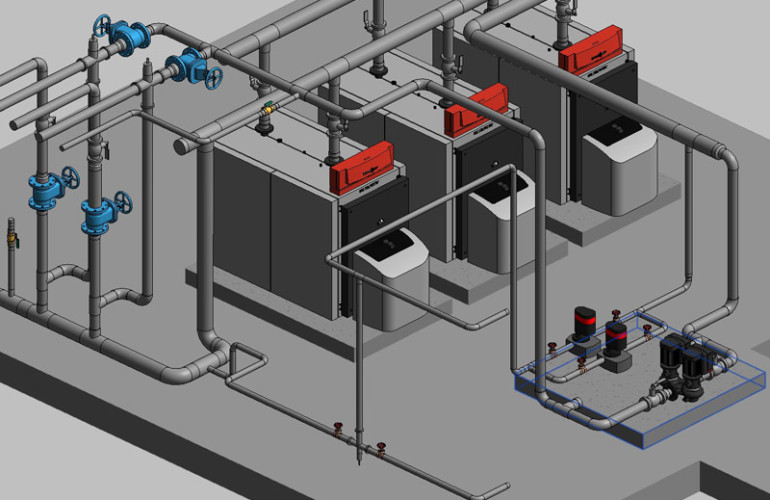

To use high efficiency LED lighting and air conditioning to serve the building without exceeding the capacity of the existing gas and electrical supplies. To carry out a full psychrometric analysis of the laboratories using the rigorous internal conditions so that plant duties and sizes could be accurately calculated. To integrate the extension in sympathy with the existing building. To ensure that new plant would fit in the existing plant room and that structural load capacities to the new roof would not be exceeded.

Engineering and Design

The laboratories need to be fully operable to:

- All season operation

- Internal Temperature of 19°C +/-1°C

- Relative Humidity 50-60% +/-5%

- 28 people – 8 of which are exercising.

Cooling loads are split into sensible loads (heat only) and latent loads (moisture). Latent loads arise where there is water vapour in fresh air or respiration. Both must be addressed in cooling calculations so that plant is correctly sized.

Our Approach

We worked closely with the University team to interrogate the laboratory requirements, the occupancy levels, the equipment in the spaces – anything that could affect the heating and cooling load to the labs was identified and quantified.

We ran through various options to ensure that the scheme could be engineered within the tender budget.

We produced a full detailed design package for the mechanical and electrical building services covering heating and cooling, ventilation, piped services, lighting, small power and life safety systems.

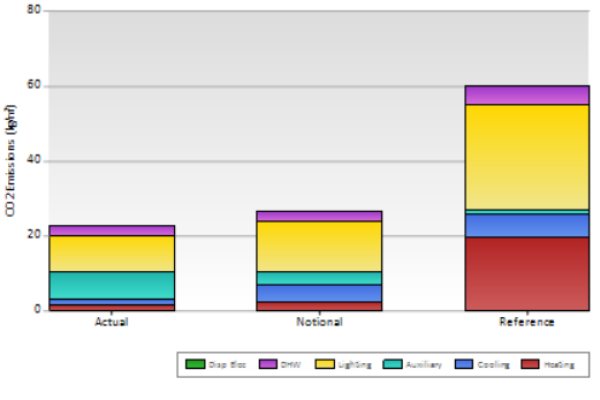

Dynamic thermal analysis using EDSL TAS software was used to develop the energy model for the building so that the Part L calculations and building heating and cooling loads could be produced.

An electrical load analysis identified the extra draw on the existing supply capacity and we were able to confirm that no extra electrical infrastructure would be required.

New plant was designed to fit within the constraints of the existing plant room and the structural load bearing capacity of the new roof.

Lighting design was carried out using ReluxPro. Detailed design installation drawings were produced in Autocad.

Outcomes

A fully operational high standard laboratory facility Coordinated Building Services Design Harmonious integration of extension into the existing building within the capacity of the utility services.